Biogas comprises approximately 55% methane (CH4) and 45% carbon dioxide (CO2), resulting from the anaerobic digestion or methanisation of organic matter, a process excluding oxygen. The feedstock for biogas production varies, encompassing both second-generation waste and first-generation crops.

???Fueling

sustainable

future???

Biomethane

Turning waste into value

Upon undergoing an upgrading process, biogas transforms into biomethane. This biomethane, akin to natural gas, exhibits identical technical specifications suitable for diverse applications, including heating, process energy, and fuel use. Its multifunctional attributes align with sustainability objectives.

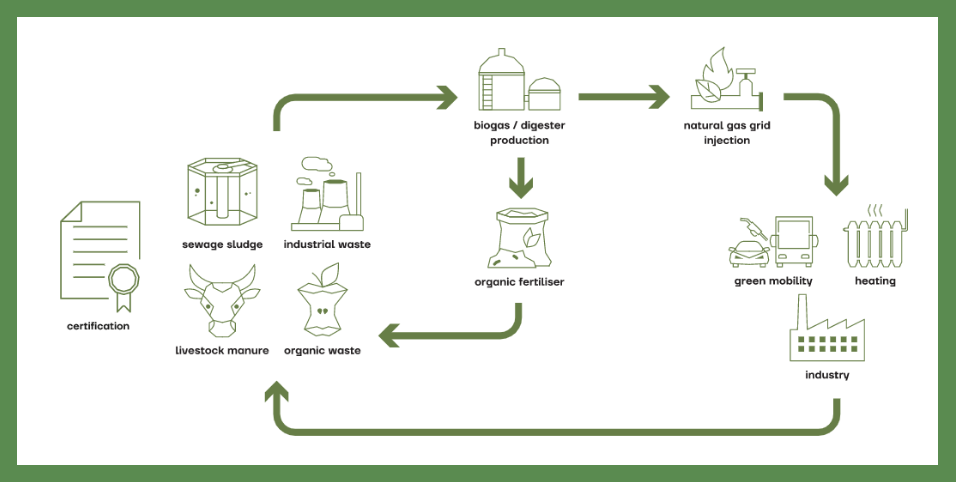

Biogas in the circular economy

In this innovative process, organic waste is converted into valuable biogas through anaerobic degstion. Biomethane not only reduces greenhous gas emissions, but also provides a reliable and clean energy for various applications. By closing the loop and repurposing waste, the ciruclar economy of biogas promotes resource efficiency, environmental presevation and paves the way for a sustainable tomorrow.

Why is the cooperation between farmers and

producers highly beneficial?

Farmers provide the organic materials needed for biogas production, ensuring a consistent energy source. This approach is sustainable, as it repurposes agricultural waste and boosts local economies. This cooperative model also promotes knowledge sharing between the two groups, leading to improved practices. While the concept applies broadly, implementing it requires overcoming logistical and communication challenges. Overall, it’s a promising approach but demands careful planning and ongoing teamwork.

Does this concept also hold relevance for other biogas sites?

Absolutely! The key principles of utilizing local resources, reducing waste, and building strong partnerships apply universally. This approach can enhance sustainability and provide a steady supply of feedstock for biogas production in various locations. However, adapting the concept to different contexts might involve addressing specific logistical and operational challenges.

Is its implementation challenging?

Implementing this concept can indeed be challenging. It requires aligning the interests and efforts of both farmers and producers, establishing effective communication channels, and ensuring a fair distribution of benefits. Coordinating logistics, managing expectations, and overcoming potential resistance are some of the hurdles that need to be navigated. However, with careful planning, commitment, and a collaborative mindset, these challenges can be overcome to create a successful and mutually beneficial partnership.

Where were the primary challenges encountered? Are there persisting challenges that remain relevant today?

The main challenges were primarily centered around coordination and communication. Getting farmers and producers on the same page in terms of timing, expectations, and objectives was often a hurdle. Practical aspects like transportation and waste collection logistics could also present difficulties.

Regarding enduring challenges, some aspects persist today. Securing a consistent supply of organic materials for biogas production remains a logistical puzzle. Moreover, evolving regulations and market dynamics can impact the economic feasibility of these collaborations. Successfully navigating change while upholding the collaborative spirit remains an ongoing test. Tackling these ongoing issues effectively necessitates proactive communication and adaptable problem-solving.

Foersom

Bioenergi

a biogas

plant

Morbi sodales, augue eget dictum dapibus, orci massa cursus libero, a posuere massa justo placerat dui. Donec porta ligula sed volutpat aliquet. Nullam viverra massa at nunc facilisis scelerisque. Etiam dictum condimentum arcu ac varius. Nam ut enim vel dolor suscipit porta.

Clay Johnson

Europe Business Director

Waste-Energy-Fertilizer-Waste,

an example of Foersom Bioenergi

tailor-made fertilizer for farmers and security of

biomass supply for producers of biomethane:

Moreover, the partnership goes beyond just biomass procurement, as the plant has

introduced a pioneering initiative by producing tailor-made fertilizers designed to cater

to the specific needs of these farmers, exemplifying the plant’s commitment to

holistic agricultural enhancement.

A small FaQ section

about the Foersom

Bioenergi plant

What is tailor-made fertiliser?

In Denmark, a cutting-edge approach is reshaping agriculture. With strict rules on nitrogen and phosphorus use, farmers often hit the « phosphorus ceiling » first, leading to extra costs for nitrogen fertilizers.

Enter the game-changing « tailormade fertilizer. » Here’s the scoop: Biogas plants and suppliers team up, using technology to split biogas byproducts into liquid (nitrogen-rich) and solid (phosphorus-rich) components. Mixing these parts creates a perfect nutrient balance for crops as required by suppliers. This means less need for commercial fertilizers, benefiting the environment. The leftover phosphorus-rich solid can fuel processes like pyrolysis for energy or enrich soil as a fertilizer.

This innovation might not directly grow more plants, but it’s a win-win for farmers. It simplifies nutrient management, reducing their reliance on external sources. This forward-thinking solution boosts sustainability and productivity in Danish agriculture.

What was the biggest challenge in building a biogas plant?

The plant was built within a year. Building a biogas plant is a complex undertaking, regardless of the timeline. When you factor in a strict and tight deadline, the challenge becomes monumental. Nevertheless, the team’s exceptional effort combined with the assistance of dedicated local stakeholders made it possible to successfully build and commission the plant.

What is the current status of the planned expansion plans?

for phase 2 to kick off, phase 1 needs to wrap up. This involves transitioning the control system at Foersom Bioenergi into a comprehensive SCADA system that integrates all sub-elements. Overall, the facility needs those final touches, and approximately 40% of the work remains to be done for its completion. Simultaneously, all necessary permits are in the process of being secured.

Do want to know more about

Biomethane and our solutions ?

Lorem ipsum dolor sit amet, consectetur adipiscing elit,

sed doeiusmod tempor incididunt ut labore et dolore.